care@electrohydraulicscontrols.com

Login / Register

Login

Register

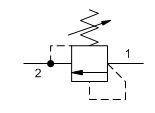

SUN HYDRAULICS Direct-acting relief valve (RDDALBN)

£204.00

Direct-acting relief cartridges are normally closed, pressure-limiting valves used to protect hydraulic components from pressure transients. When the pressure at the inlet (port 1) reaches the valve setting, the valve starts to open to tank (port 2), throttling flow to limit the pressure rise. These valves are smooth and quiet, essentially zero leak, dirt tolerant, immune to silting and are very fast.

- All 2-port relief cartridges (except pilot reliefs) are physically and functionally interchangeable (same flow path, same cavity for a given frame size).

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

- The seals on the adjust screw are exposed to system pressure which means this valve can only be adjusted when the pressure is removed. The setting procedure is; check the setting, remove the pressure, adjust the valve, check the new setting.

- Valve is relatively insensitive to varying oil temperatures and oil borne contamination.

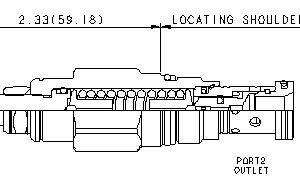

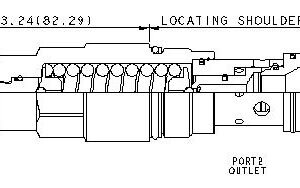

SUN HYDRAULICS Direct-acting relief valve (RDDALEN)

£211.20

Direct-acting relief cartridges are normally closed, pressure-limiting valves used to protect hydraulic components from pressure transients. When the pressure at the inlet (port 1) reaches the valve setting, the valve starts to open to tank (port 2), throttling flow to limit the pressure rise. These valves are smooth and quiet, essentially zero leak, dirt tolerant, immune to silting and are very fast.

- All 2-port relief cartridges (except pilot reliefs) are physically and functionally interchangeable (same flow path, same cavity for a given frame size).

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

- The seals on the adjust screw are exposed to system pressure which means this valve can only be adjusted when the pressure is removed. The setting procedure is; check the setting, remove the pressure, adjust the valve, check the new setting.

- Valve is relatively insensitive to varying oil temperatures and oil borne contamination.

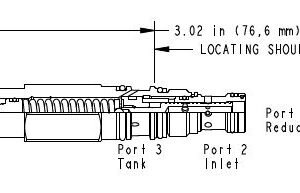

SUN HYDRAULICS Direct-acting relief valve (RDHALAN)

£638.40

Direct-acting relief cartridges are normally closed, pressure-limiting valves used to protect hydraulic components from pressure transients. When the pressure at the inlet (port 1) reaches the valve setting, the valve starts to open to tank (port 2), throttling flow to limit the pressure rise. These valves are smooth and quiet, essentially zero leak, dirt tolerant, immune to silting and are very fast.

- All 2-port relief cartridges (except pilot reliefs) are physically and functionally interchangeable (same flow path, same cavity for a given frame size).

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

- The seals on the adjust screw are exposed to system pressure which means this valve can only be adjusted when the pressure is removed. The setting procedure is; check the setting, remove the pressure, adjust the valve, check the new setting.

- Valve is relatively insensitive to varying oil temperatures and oil borne contamination.

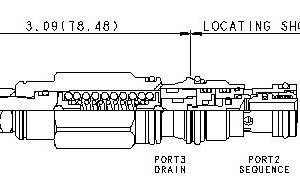

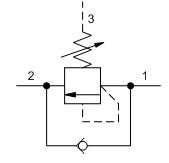

SUN HYDRAULICS Direct-acting sequence valve with reverse flow check(SCCALCN)

£360.00

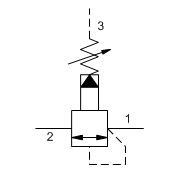

Direct-acting sequence valves with reverse-flow check will supply a secondary circuit with flow once the pressure at the inlet (port 1) has exceeded the valve setting. Additionally, these valves incorporate an integral check valve to provide reverse flow from port 2 (sequence) to port 1 (inlet). The pressure setting of a sequence valve controls the pressure at port 1 relative to the pressure at the drain (port 3).

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- All 3 port sequence cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size).

- Although this is a zero pilot flow valve, port 3 (drain) must be connected to maintain a pressure reference in the control chamber. If port 3 is blocked, reciprocating seal weepage will cause the valve to malfunction.

- Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 5000 psi (350 bar).

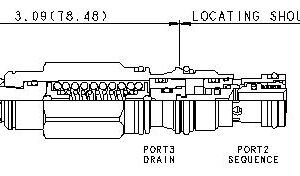

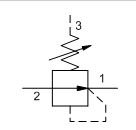

SUN HYDRAULICS Direct-acting sequence valve with reverse flow check(SCCALDN)

£357.60

Direct-acting sequence valves with reverse-flow check will supply a secondary circuit with flow once the pressure at the inlet (port 1) has exceeded the valve setting. Additionally, these valves incorporate an integral check valve to provide reverse flow from port 2 (sequence) to port 1 (inlet). The pressure setting of a sequence valve controls the pressure at port 1 relative to the pressure at the drain (port 3).

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- All 3 port sequence cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size).

- Although this is a zero pilot flow valve, port 3 (drain) must be connected to maintain a pressure reference in the control chamber. If port 3 is blocked, reciprocating seal weepage will cause the valve to malfunction.

SUN HYDRAULICS Direct-acting sequence valve with reverse flow check(SCCALWV)

£369.60

Direct-acting sequence valves with reverse-flow check will supply a secondary circuit with flow once the pressure at the inlet (port 1) has exceeded the valve setting. Additionally, these valves incorporate an integral check valve to provide reverse flow from port 2 (sequence) to port 1 (inlet). The pressure setting of a sequence valve controls the pressure at port 1 relative to the pressure at the drain (port 3).

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- All 3 port sequence cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size).

- Although this is a zero pilot flow valve, port 3 (drain) must be connected to maintain a pressure reference in the control chamber. If port 3 is blocked, reciprocating seal weepage will cause the valve to malfunction.

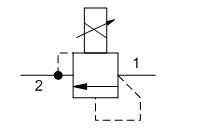

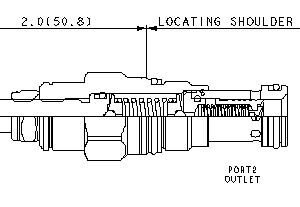

SUN HYDRAULICS Direct-acting, pressure reducing valve(PRBRLBN)

£355.20

Direct-acting, pressure reducing valves reduce a high primary pressure at the inlet (port 2) to a constant reduced pressure at port 1. These valves incorporate a damped construction for stable operation allowing the use of high reduced pressure.

- Note: This valve has no relieving capability. It should not be used in a dead-headed application. If the reduced pressure side of the circuit has very low leakage the pressure may rise significantly. The pressure rise will vary from valve to valve.

- This type of valve, PR*R, is a good replacement for an LP*C as a normally open, restrictive compensating element if a higher pressure drop across an orifice is needed.

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Full reverse flow from reduced pressure (port 1) to inlet (port 2) may cause the main spool to close. If reverse free flow is required in the circuit, consider adding a separate check valve to the circuit.

SUN HYDRAULICS Electro-proportional relief valve – pilot capacity(RBAPXAN)

£604.80

This 2-port, pilot-stage, direct-acting relief cartridge is an electro-proportionally controlled, pressure regulating valve. The proportional control allows for infinite, step-less adjustability within the selected pressure range. When the pressure at port 1 (inlet) is sufficient to overcome the solenoid forces, as determined by the analog input signal, the poppet lifts and allows flow from port 1 to port 2 (outlet). This pilot control cartridge utilizes the T-8A cavity so it can be used in conjunction with Sun's main stage, pressure control elements.

- Varying the analog input signal to the proportional solenoid provides a step-less control of pressure.

- This electro-proportional cartridge utilizes the Sun T-8A, 2-port cavity making it the ideal choice to use in conjunction with Sun's main stage cartridges. Separate pilot lines are eliminated and only one cavity needs to be machined to accommodate both the control and primary function. Note: All 2-port pilot stage control cartridges utilize the same cavity and are physically interchangeable. Functionality is the only consideration.

- All pressure ranges will drop to a setting of 0 with no analog input signal. The pressure ranges indicate the valve's area of acceptable performance.

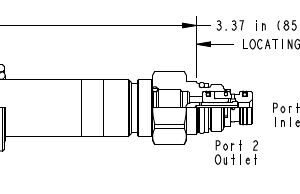

SUN HYDRAULICS Electro-proportional, direct-acting, pressure reducing/relieving valve with open transition (PRDLMDN2B24A)

£1,958.40This electro-proportional, direct-acting reducer/reliever valve reduces a high primary pressure at the inlet (port 2) to a constant reduced pressure at port 1, with a full flow relief function from port 1 to tank (port 3). The valve is biased to the relieving mode. Energizing the coil connects port 2 to port 1. Increasing the current to the coil will proportionally increase the reduced pressure at port 1. If pressure at port 1 exceeds the setting induced by the coil, pressure at port 1 is relieved to port 3. This valve is open in the transition from reducing to relieving. It provides good pressure control and dynamic response. Optional full manual control is available.

- Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 3000 psi (210 bar).

- Maximum pressure at port 3 should be limited to 3000 psi (210 bar).

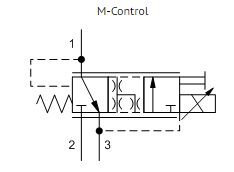

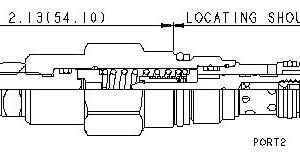

SUN HYDRAULICS Electro-proportional, direct-acting, pressure reducing/relieving valve with open transition(PRDLMBN)

£756.00

This electro-proportional, direct-acting reducer/reliever valve reduces a high primary pressure at the inlet (port 2) to a constant reduced pressure at port 1, with a full flow relief function from port 1 to tank (port 3). The valve is biased to the relieving mode. Energizing the coil connects port 2 to port 1. Increasing the current to the coil will proportionally increase the reduced pressure at port 1. If pressure at port 1 exceeds the setting induced by the coil, pressure at port 1 is relieved to port 3. This valve is open in the transition from reducing to relieving. It provides good pressure control and dynamic response. Optional full manual control is available.

- Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 3000 psi (210 bar).

- Maximum pressure at port 3 should be limited to 3000 psi (210 bar).

- Direct acting concept provides highly reliable operation in contaminated systems, especially at dead headed conditions.

SUN HYDRAULICS Fast-acting, pilot-operated, balanced piston relief valve (RPEELDN)

£252.00

Fast-acting, pilot-operated, balanced piston relief cartridges are normally closed, pressure-limiting valves used to protect hydraulics components from pressure transients. Fast opening and closing is gained at the expense of smoothness. When the pressure at the inlet (port 1) reaches the valve setting, the valve starts to open to tank (port 2), throttling flow to limit the pressure rise. These valves have low pressure rise vs. flow and are very fast.

- All 2-port relief cartridges (except pilot reliefs) are physically and functionally interchangeable (same flow path, same cavity for a given frame size).

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits. If used in cross port relief circuits, consider spool leakage.

- Main stage orifice is protected by a 150-micron stainless steel screen.

- Not suitable for use in load holding applications due to spool leakage.

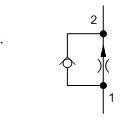

SUN HYDRAULICS Fixed orifice pressure compensated flow control valve with reverse flow check (FCBBLAN)

£271.20

Fixed-orifice, pressure-compensated flow controls with reverse-flow check provide precise flow regulation for meter-in or meter-out applications where there may be wide pressure fluctuations. An integral high-capacity check valve provides unrestricted flow from port 2 to port 1. The flow setting is specified by the user and is set at the factory.

- Customer must specify a flow rating. Factory set flow ratings are within +/- 15% of the requested setting.

- The tuneable control option provides +/- 20% variation from the nominal factory pre-set flow. Turn the adjustment clockwise to increase.

- All 2-port flow control cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size). However, cartridge extension dimensions from the mounting surface may vary.

- The sharp-edged orifice design minimizes flow variations due to viscosity changes.

Product categories

- Accessories

- Chrome Rods

- Honed Tubes

- Hydraulic Accumulator

- Hydraulic Cylinders

- Hydraulic Filters

- Hydraulic Manifold Blocks

- Hydraulic Motors

- Hydraulic Power Units

- Hydraulic Pumps

- Hydraulic Seals

- Hydraulic Solutions

- Hydraulic Valves

- Lubrication

- Mobile Controls

- Onsite and Offsite Training

- Tractor Accessories

- Tractor Pump